Basca WM A250-30 is the world's most advanced machine for cleaning IBC's & Mixing Tanks, it allow your company to:

Reduce water consumptions from cleaning IBC's & Tank cleaning

Increase the quality of cleaning & reducing cross contamination from products

Limit manual workforce for performing low added value activities

Convert cleaning process in a full safety procedure

Reduce the waste generated by cleaning activities

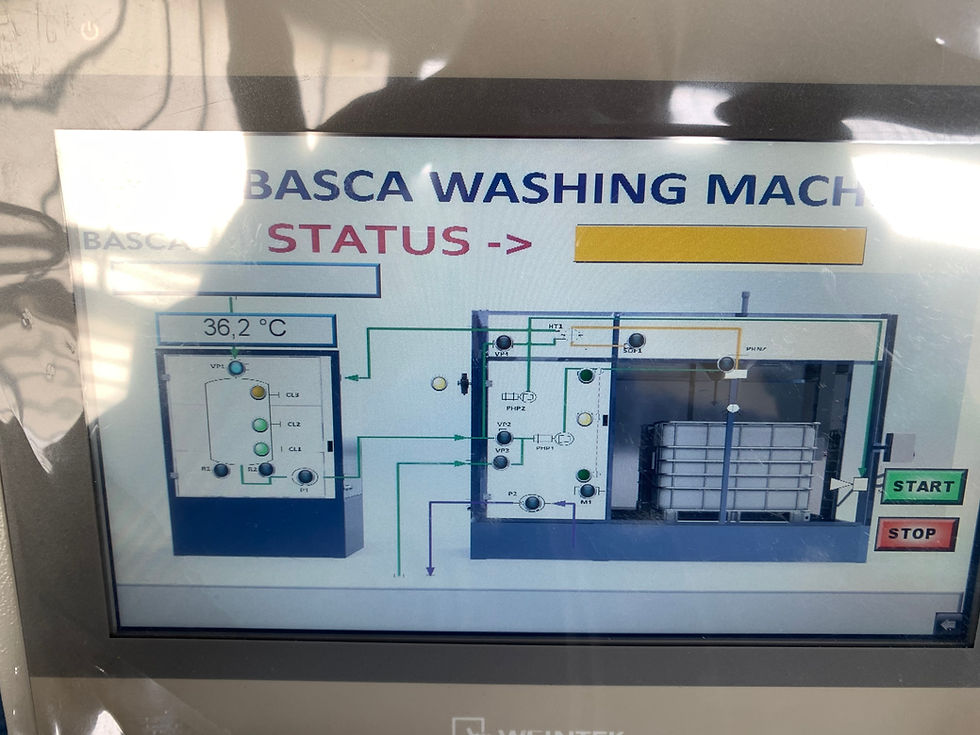

Basca WM A250-30 has been engineered to perform cleaning process at it's best with hot water 80° and a 250 Bar pressure. The washing cycle is composed of prewash, wash, rinsing, sanitizing and drying, all automatically manage by a Siemens PLC control system with a 10" HMI panel. The machine is capable of performing different cleaning programs for heavy, standard or slightly dirty containers or any other configuration you may request. The cleaning chamber is fully AISI 304 stainless steel for optimal resistant to different chemical agents and easy to clean. The machine is equipped with top quality components, stainless steel filters, high temperature 250 Bar piston pump with inox head, diaphragm pumps, inox valves and other high performances components. The machine also includes a lance and gun for high pressure cleaning of the external surfaces of containers. Cleaning of containers is done by spraying high pressure and hot water 360° over the internal surfaces by means of a inox rotary nozzle. Sanitizing cycle works with any type of sanitizing products by dosing it automatically during the cleaning process to remove bacteria, virus and fungus from the internal container volume. Drying is performed with hot air obtained from recovering heat from hot water to reduce energy consumption. The machine integrated with a Basca BS1000 stocking tank, manufactured in AISI 304 stainless steel and equipped with heating elements to warm up water.

For more information visit www.basca.tech/basca-wm

Comments